When NASA prints rocket engine components using metal powder, when doctors save patients' lives with customized implants, and when automobile manufacturers shorten research and development cycles by months through rapid prototyping, 3D printing technology has long moved beyond the realm of "conceptual innovation" to become a core force reshaping the production logic of the global manufacturing industry. Known as "additive manufacturing," this technology utilizes digital model-driven layer-by-layer deposition to break the geometric constraints and efficiency bottlenecks of traditional subtractive manufacturing, unleashing transformative value across dozens of fields including aerospace, healthcare, and automotive manufacturing. This article will delve into the technical system of 3D printing, systematically present its industrial application landscape, and look ahead to its future development path.

I. 3D Printing Technology System: The Application Foundation Supported by Diverse Technologies

3D printing is not a single technology but a cluster of technologies encompassing seven core types and dozens of specialized processes. The International Organization for Standardization (ISO) classifies it into seven categories—including material extrusion, vat photopolymerization, and powder bed fusion—based on molding principles and material properties. Among these, four core technologies have achieved large-scale industrial application, forming the technical cornerstone of the industry's development.

Fused Deposition Modeling (FDM), the most widely adopted "mass-market technology," melts filaments such as PLA and ABS at a high temperature of 200°C and deposits them layer by layer with a precision of 0.1mm via a computer-controlled nozzle. Its key advantages lie in low equipment costs (ranging from hundreds of dollars for desktop printers to millions for industrial-grade machines) and a wide range of material options. It can process not only conventional plastics but also metals, concrete, and even food. In education, FDM desktop printers have become standard equipment in university innovation laboratories; in industrial settings, FDM industrial printers from brands like Stratasys are responsible for manufacturing production tools such as jigs and molds.

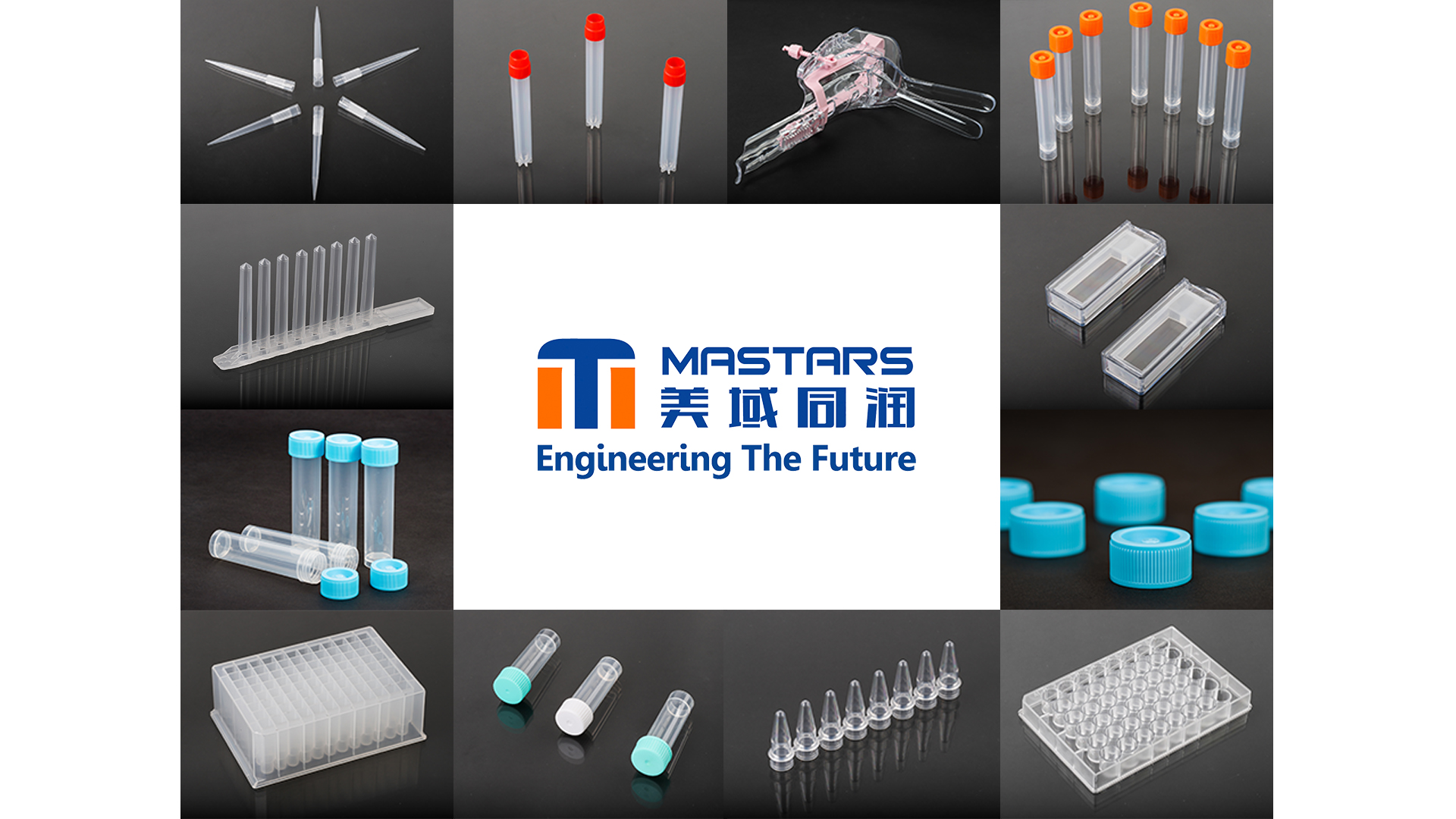

Stereolithography (SLA) uses liquid photosensitive resin as raw material and achieves micron-level precision molding through selective ultraviolet (UV) light irradiation, essentially "sculpting" solid objects with light. The latest models from UnionTech can achieve a layer thickness precision of 25μm—equivalent to one-third the diameter of a human hair—and can print organ models with blood vessel walls as thin as 0.2mm in the medical field. Its unparalleled surface finish and detail reproduction capabilities make it the preferred solution for high-end customization fields such as jewelry and precision medical models. However, its higher material costs and the need for post-curing treatment limit its application in some scenarios.

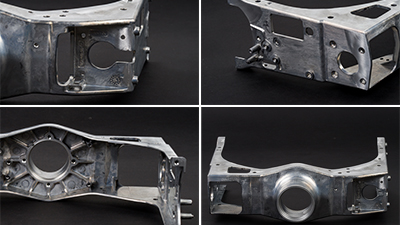

Selective Laser Sintering (SLS) utilizes a 400W laser beam to precisely sinter powder materials, enabling the phase transformation from powders (such as nylon and titanium alloy) to dense solid parts. Its ability to operate without support structures (unsintered powder naturally provides support) makes it ideal for manufacturing complex internal structural components. In aerospace, lightweight parts printed via SLS technology meet both strength and weight reduction requirements; in automotive manufacturing, complex intake manifold systems produced using this technology can be directly installed in vehicles.

Three-Dimensional Printing (3DP) achieves powder molding by jetting binders through nozzles, with high speed and efficiency as its core advantages, enabling the production of large-scale models in a short time. In architectural design, designers use 3DP technology to quickly convert blueprints into physical models; in cultural and creative industries, this technology supports the mass customization of personalized cultural and creative products.

These four core technologies serve as the "four pillars" of 3D printing, each addressing key challenges in terms of cost, precision, material adaptability, and efficiency, collectively supporting an application ecosystem across multiple industries.

II. Key Industrial Applications: Translating Value from Laboratories to Production Sites

The transformative value of 3D printing is ultimately realized through its application in specific industries. In fields with high demands for precision and customization—such as aerospace, healthcare, and automotive manufacturing—this technology is evolving from an auxiliary tool to a core production method, driving dual improvements in industry efficiency and quality.

(1) Aerospace: A Lightweight Revolution Breaking Physical Constraints

The aerospace industry imposes three strict requirements on components: quality, precision, and weight reduction. 3D printing has emerged as a key solution to this challenge. Complex lattice structures and hollow sandwich designs, which are difficult to achieve with traditional processing methods, become feasible with additive manufacturing, directly enhancing the performance of aerospace components.

In aircraft manufacturing, industrial-grade 3D printing solutions from Stratasys have enabled the mass production of critical components such as turbine blades and airframe parts. Through topological optimization design, these printed parts reduce weight by over 30% compared to traditional components while maintaining mechanical performance, directly lowering fuel costs for airlines. NASA regards 3D printing as a core enabler of space exploration: the rocket engine combustion chambers it prints using SLS technology not only reduce the manufacturing cycle by 90% but also withstand extreme high-temperature and high-pressure environments.

The improvement in material utilization is equally significant. Traditional machining of aerospace components often results in a material waste rate of up to 90%, while the additive nature of 3D printing pushes material utilization above 95%. For expensive aerospace materials like titanium alloy, this translates to a substantial reduction in manufacturing costs. More importantly, 3D printing enables a shift toward "design-driven manufacturing"—engineers no longer need to compromise on design for the sake of processing technology but can instead design purely based on performance requirements. This freedom is fostering a wave of design innovation in the aerospace sector.

(2) Healthcare: The Precision Implementation of Customized Medicine

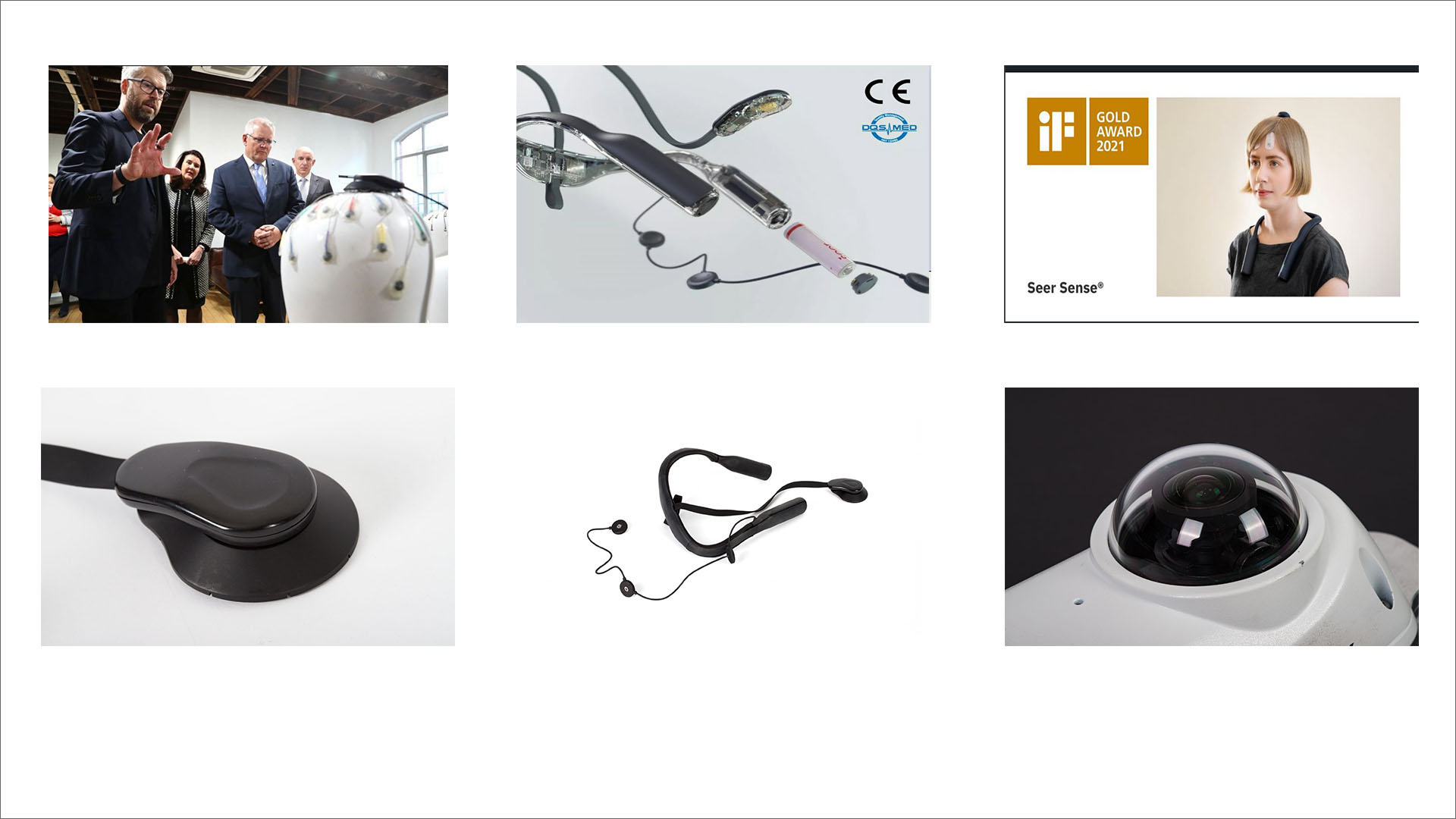

Individual differences in the medical field limit the effectiveness of "standardized" solutions, and 3D printing’s advantages in personalization are fully demonstrated here. From customized implants to surgical simulation models, from dental restorations to bioprinting of tissues, this technology is reshaping the delivery model of medical services.

In implant manufacturing, 3D printing enables "patient-specific" precision medicine. Using a patient’s CT scan data, doctors can design implants that perfectly match the patient’s bone structure via CAD software, then print them using titanium alloy powder with SLS technology. Stratasys’ high-performance printing platforms ensure micron-level surface roughness for implants; this bionic structure promotes the attachment and growth of bone cells, significantly improving implant success rates. In dentistry, traditional denture production requires multiple steps—including impression taking and mold casting—and takes up to a week. In contrast, 3D printing can produce customized dentures within 24 hours, with significantly improved fit and comfort.

During surgical preparation, 3D-printed anatomical models serve as "practical guides" for doctors. For complex heart surgeries, doctors can use 1:1 printed heart models to clearly observe blood vessel pathways and lesion locations, simulate surgical approaches in advance, and develop contingency plans. Data shows that surgeries assisted by 3D-printed models see an average 15% increase in success rates and a 20% reduction in operation time.

More forward-looking is the breakthrough in biological 3D printing—a specialized branch of material extrusion technology. Using bioinks containing living cells, it constructs 3D structures similar to human tissues through precise extrusion molding. Currently, it can print simple tissue models such as blood vessels and skin, which are used in drug toxicity testing and regenerative medicine research. In the future, it is expected to enable clinical applications of artificial organs, fundamentally solving the shortage of donors for organ transplantation.

(3) Automotive Manufacturing: Dual Acceleration in R&D and Production

Intense competition in the automotive industry is pushing companies to continuously shorten R&D cycles and reduce manufacturing costs. In this process, 3D printing acts as an "efficiency accelerator," with its applications expanding from early prototyping to mold manufacturing and even mass production of components.

In R&D, 3D printing has completely transformed the traditional "design-prototyping-modification" cycle. In the past, developing the exterior components of a new car required 3–6 months just for mold production; with FDM technology for prototyping, this cycle can be shortened to a few days. Stratasys once assisted a new energy vehicle brand in completing the design of an electric vehicle shell, with the entire process—from concept verification to functional testing—taking only 45 days, saving 3 months compared to traditional methods. This rapid iteration capability allows companies to respond faster to market demands and gain an edge in the new car competition.

In component production, 3D printing’s advantages in lightweighting are equally prominent. The range of electric vehicles is directly related to vehicle weight; aluminum alloy support structures printed via SLS technology are 40% lighter than traditional steel structures while meeting strength requirements. Automakers such as BMW and Tesla have begun mass-producing customized components using 3D printing, which not only reduces vehicle weight but also simplifies the supply chain—structures that previously required assembly of multiple parts can now be manufactured as a single piece via integrated printing.

Mold manufacturing is another key application scenario for 3D printing in the automotive industry. Traditional mold manufacturing is time-consuming, costly, and struggles to achieve complex internal cavity structures. In contrast, resin molds printed via SLA technology reduce the manufacturing cycle by 50% and can incorporate conformal cooling channels, cutting the cooling time of injection-molded parts by 30% and significantly improving production efficiency.

(4) Cross-Industry Expansion: Penetration from Industry to Daily Life

Beyond the core fields mentioned above, 3D printing is rapidly penetrating into architecture, education, and cultural and creative industries, demonstrating strong adaptability to diverse scenarios.

The construction industry is undergoing a construction revolution driven by 3D printing. Large gantry-style printers extrude concrete materials to enable the automated construction of buildings. This method not only reduces labor demand by 60% but also cuts construction waste by over 50%. Dozens of 3D-printed houses have already been built in the United States and Europe, and research institutions are developing technologies to print habitats using lunar soil, supporting space exploration.

Education has become a key popularization scenario for 3D printing. Universities integrate FDM desktop printers into innovation laboratories, allowing students to transform abstract mechanical designs and architectural models into physical objects, greatly enhancing their practical skills. Educational printers from Stratasys have been adopted by many institutions; their stable performance ensures the smooth progress of teaching activities and cultivates reserve talents with additive manufacturing thinking for the manufacturing industry.

In cultural and creative industries, 3D printing enables personalized expression. Museums use 3DP technology to replicate precious cultural relics, realizing cultural heritage preservation while avoiding the risk of damaging original artifacts. Jewelry designers use SLA technology to produce intricate molds, quickly transforming creative concepts into finished products. Even in the food industry, FDM-derived chocolate printers and pizza printers are redefining the personalized model of food production.

III. Challenges and Trends: Industrial Evolution Amid Technological Iteration

Despite the widespread adoption of 3D printing across industries, it still faces numerous challenges in large-scale application. The incomplete material system is a core bottleneck—currently, there are only hundreds of commercial 3D printing materials, far fewer than the tens of thousands available for traditional manufacturing. Additionally, high-performance materials are mostly monopolized by foreign enterprises, keeping prices high.

Insufficient printing efficiency and scalability also hinder industrial development. The printing speed of industrial-grade equipment still cannot meet the demands of large-scale mass production, while the precision and stability of desktop-grade equipment need improvement. Furthermore, issues such as the lack of industry standards and an inadequate intellectual property protection system affect the standardized development of the technology.

However, these challenges are driving accelerated industry iteration, and 3D printing will exhibit three key development trends in the future:

-

Material innovation will be a breakthrough point. On one hand, the cost of high-performance metals and ceramics will gradually decrease; on the other hand, specialized materials such as biocompatible and biodegradable materials will achieve breakthroughs, supporting applications in more high-end scenarios.

-

Technology integration will become the mainstream direction. The combination of 3D printing with artificial intelligence (AI) and the Internet of Things (IoT) will enable intelligent monitoring and quality traceability during the printing process. Integration with digital twin technology will allow parameter optimization in virtual environments, significantly improving yield rates.

-

Application scenarios will be further deepened. The industry will shift from single-component manufacturing to "structure-function integrated" printing. For example, in aerospace, this means printing intelligent components with built-in sensors; in healthcare, it involves manufacturing implants with drug delivery functions.

Conclusion: From Technological Innovation to Industrial Transformation

The value of 3D printing has long transcended its role as a "manufacturing tool" to become a core engine driving industrial upgrading. It breaks the geometric constraints of traditional manufacturing, enabling a shift from "standardized production" to "personalized customization"; it restructures production processes, making "design-driven manufacturing" a reality; and it reshapes the industrial landscape, allowing small and medium-sized enterprises to achieve innovation at lower costs.

From Stratasys’ industrial-grade solutions to UnionTech’s high-precision equipment, from NASA’s rocket components to hospital-customized implants, 3D printing application cases continue to expand. As material systems improve, printing efficiency increases, and costs decrease, this technology will evolve from an "enhancing auxiliary tool" to an "indispensable core production method," sparking in-depth production revolutions across more industries.

For enterprises, seizing the opportunities brought by 3D printing is not just a matter of technology selection but also a transformation of production thinking. In this industrial revolution led by additive manufacturing, only those entities that proactively embrace technology and restructure production logic will gain an advantage in future competition.