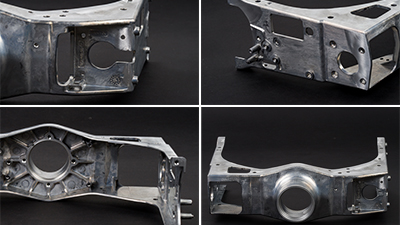

I. Project Background and Technical Challenges

The brake housing for a certain automobile model is a core safety

component of the braking system, required to withstand high pressure,

high-frequency vibrations, and extreme temperature cycles (-40°C to 150°C).

Brake housings produced by traditional zinc alloy die casting often faced the

following issues:

-

Porosity

Defects: Gas entrapment during

conventional die casting led to high internal porosity rates of 3%-5% in

the components. X-ray inspection revealed porosity concentrated around

bolt connection surfaces, easily causing leakage during hydraulic pressure

tests

.

-

Uneven

Solidification: Significant

variations in brake housing wall thickness (ranging from 2-8mm), combined

with insufficient traditional mold temperature control, resulted in

shrinkage cavities in thick sections and incomplete filling in thin

sections, limiting the yield rate to only 85%

.

-

Failure to

Meet Mechanical Properties:

Porosity and shrinkage defects caused fluctuations in the tensile strength

of the parts between 200-240 MPa, below the design requirement of 280 MPa,

and also led to deformation after heat treatment

.

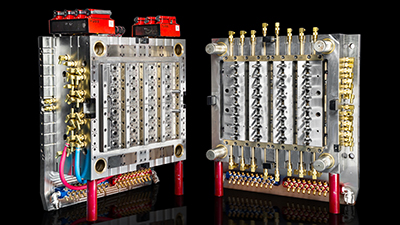

II. Collaborative Solution: Vacuum Die Casting and In-Mold Temperature

Control

1. High-Vacuum Die Casting System Modification

The foundry employed a multi-stage vacuum system to evacuate the mold

cavity to an absolute pressure above 90 kPa before injection. Specific measures

included:

-

Direct Mold

Venting Design: Eight

vacuum valves were arranged on the parting line, coupled with a sealing

structure (parting line flatness ≤0.02mm/m²), ensuring evacuation within

0.5 seconds and reducing oxygen content in the cavity to below 0.1%

.

-

Real-time

Monitoring and Interlock: The vacuum

system was interlocked with the die casting machine, utilizing pressure

sensors for real-time monitoring to prevent molten metal backflow. This

modification reduced gas content in the castings from 15 ml/100g to 2

ml/100g, bringing the porosity rate below 0.5%

.

2. Stepped In-Mold Temperature Control Technology

To address uncontrolled solidification sequencing, an active

temperature-controlled mold was developed:

-

Zoned

Heating/Cooling System: Twelve sets

of heating cartridges (400W power) and thermocouples were embedded in key

mold areas (e.g., gate, thick sections). Software configured temperature

gradients: gate zone 415°C, thick wall zone 400°C, thin wall zone 430°C,

promoting sequential solidification from the far end of the cavity back to

the gate

.

-

Dynamic

Control Strategy: Based on

thermocouple feedback, localized cooling channels were triggered when

thick section temperature dropped to 400°C to prevent shrinkage porosity,

while thin sections maintained higher temperatures to ensure complete

filling. Tests showed this approach reduced solidification time by 15% and

controlled temperature variation within ±5°C

.

3. Process Parameter Optimization

-

Injection

Pressure and Speed: A strategy

combining low-speed filling (0.5 m/s) with high-speed intensification (5

m/s) was adopted to reduce turbulent flow and gas entrapment, utilizing an

80 MPa intensification pressure to compensate for shrinkage

.

-

Alloy

Material Adaptation: A zinc

alloy with 3% copper content was selected for its superior creep

resistance compared to standard alloys, and a melting temperature of 415°C

was used to control oxide slag formation

.

III. Quality Improvement Data and Benefit Analysis

1. Significant Defect Reduction

-

Reduced

Porosity: X-ray inspection showed

internal pore size decreased from 0.5mm to below 0.1mm. Hydraulic test

pass rate increased from 82% to 99.5%

.

-

Eliminated

Shrinkage: Through mold

temperature control, the shrinkage porosity rate in thick sections dropped

from 8% to 0.3%. Metallographic analysis of sample sections showed a 40%

improvement in microstructure density

.

2. Achieved Mechanical Properties

The vacuum die cast parts achieved a consistent tensile strength of

290-310 MPa, with elongation increasing from 3% to 4.5%. They could withstand

T5 heat treatment (150°C / 2 hours) without deformation

.

3. Economic Benefits

-

The increase

in yield rate led to an 18% reduction in unit cost. For an annual

production of 100,000 pieces, this translated to approximately 2 million

RMB saved in scrap reduction.

-

Although

energy consumption of the vacuum system increased by 12%, the reduction in

subsequent processing (e.g., welding repairs) resulted in an overall cost

decrease of 15%

.

IV. Technology Promotion Value

This case demonstrates the feasibility of combining vacuum die casting

with intelligent temperature control for zinc alloy safety components. The

solution has been extended to other parts like engine brackets and steering

knuckles, establishing a standardized approach for high-integrity die casting

(e.g., vacuum >90 kPa, mold temperature gradient control ±5°C). Future

integration with AI algorithms for dynamic regulation of vacuum and temperature

holds promise for further突破 the yield

limitations of large structural components (e.g., battery trays)

.

The successful implementation of this technical solution highlights the

significant potential of vacuum die casting and precision temperature control

in enhancing the performance and yield of zinc alloy die castings, providing an

important reference for the production of similarly demanding components.