Here is a detailed

introduction to Vacuum Casting, a pivotal technology in rapid prototyping and

low-volume manufacturing.

Vacuum Casting: A Detailed Overview

1. Executive Summary

Vacuum Casting, also known as Polyurethane

(PU) Casting or Urethane Casting, is

an advanced manufacturing process used to produce high-quality, functional

prototypes and end-use parts in small to medium volumes (typically 10-50 parts,

but up to 100+). It is renowned for replicating the properties of injection-molded

plastics without the high cost and lead time of production-grade tooling.

2. Core Principle & Process

The fundamental

principle of Vacuum Casting is replication. A

master model (a perfect 3D printed or CNC-machined pattern) is used to create a

flexible silicone mold. Under a vacuum, liquid polyurethane resin is poured

into this mold. The vacuum removes trapped air, ensuring a bubble-free,

high-fidelity copy of the master.

The process can be

broken down into these key stages:

Step 1: Creating the Master

Pattern

-

A

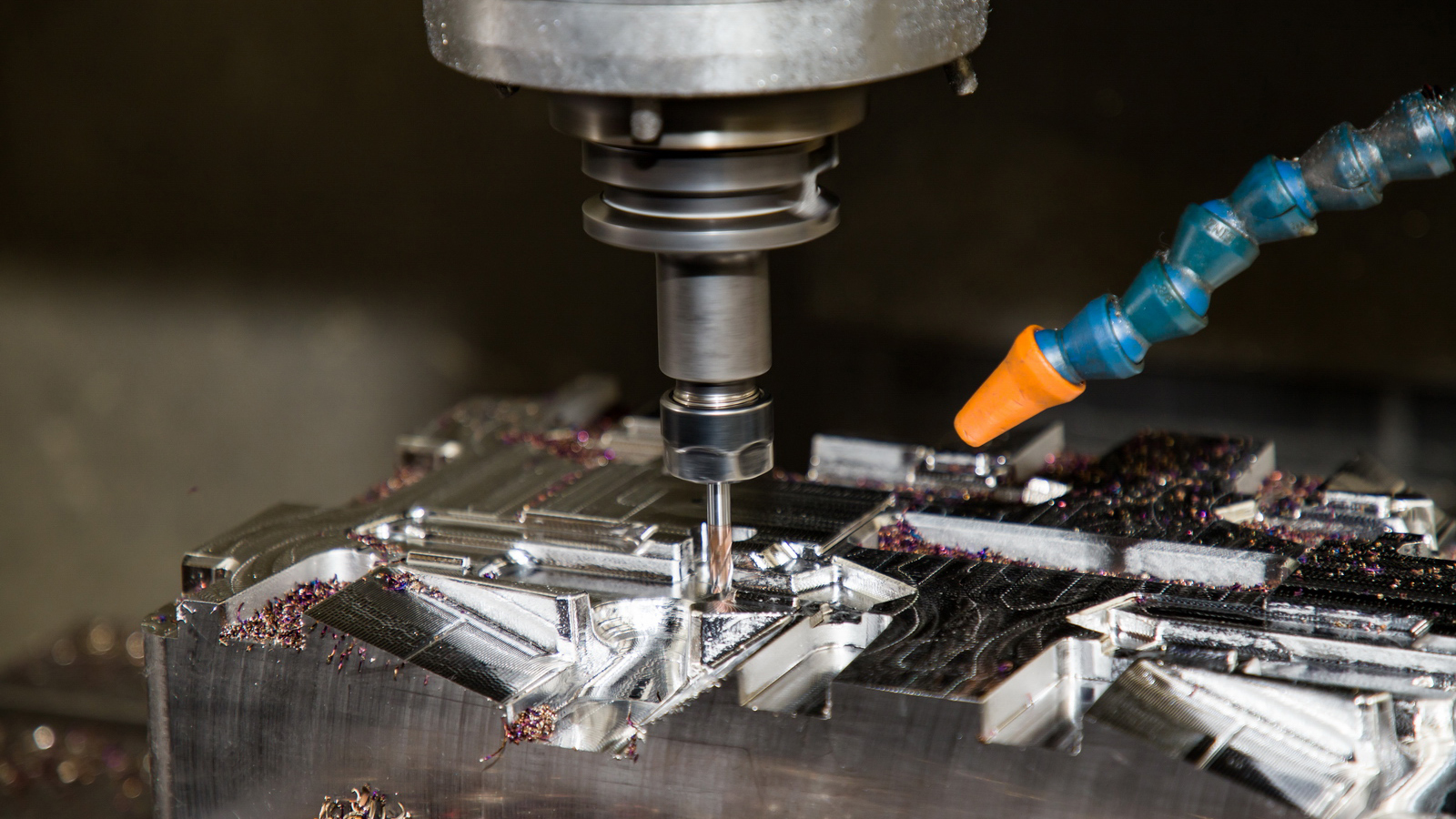

high-precision master model of the part is created. This is typically done

using SLA

(Stereolithography) or MJF (Multi Jet Fusion) 3D

printing, or CNC machining, to

achieve a flawless surface finish and accurate dimensions.

-

The master

pattern is meticulously finished (sanded, polished) and may be painted to

the desired final appearance.

Step 2: Sprueing and Mounting

-

The

master pattern is attached to a "spruing system" (gates and

runners) using wax rods or digital sprues. This creates channels for the

liquid resin to flow.

-

The

sprued master is then mounted onto a casting board or within a frame,

along with a pouring funnel.

Step 3: Creating the Silicone

Mold (Tooling)

-

The

mounted master is placed inside a casting box or frame.

-

A

two-part, heat-cured liquid silicone (RTV - Room Temperature Vulcanizing

silicone) is mixed and degassed in a vacuum chamber to remove air bubbles.

-

The

silicone is slowly poured over the master pattern inside the frame. The

entire assembly is then placed in a curing oven (typically at 40-70°C) for

several hours until the silicone becomes a solid, flexible block.

Step 4: Mold Cutting and Master

Removal

-

Once

cured, the solid silicone block is removed from the frame.

-

The

mold maker carefully cuts the block in half with a sharp blade. This cut

is not straight; it follows a complex path to ensure the master and

subsequent cast parts can be removed without damaging the mold cavity.

-

The

original master pattern is removed, leaving behind a perfect negative cavity

of the part within the silicone mold.

Step 5: Casting the Parts (The

Replication Cycle)

-

The

two halves of the silicone mold are closed and securely clamped.

-

Pre-measured

two-part polyurethane (PU) resin is mixed, often degassed in a vacuum

chamber to eliminate bubbles.

-

The

mold is placed into the vacuum casting machine. The

resin is poured into the mold's pouring funnel while the entire chamber is

under a vacuum.

-

The

vacuum ensures that air is evacuated from the complex cavities of the

mold, allowing the resin to fill every detail perfectly.

-

The

filled mold is then transferred to a curing oven. The PU resin cures in a

short time (30-90 minutes).

Step 6: De-molding and

Finishing

-

After

curing, the mold is opened, and the new polyurethane part is removed.

-

The

sprues and runners are cut off, and the part undergoes finishing

operations like sanding, painting, or surface texturing to meet the final

specifications.

-

The

silicone mold is now ready for the next casting cycle. A single mold can

typically produce 15-25 parts before the mold degrades and loses dimensional stability.

3. Key Characteristics & Advantages

-

Speed and

Cost-Effectiveness for Low Volumes: The

primary advantage. Creating a silicone mold is significantly faster and

cheaper than machining a steel or aluminum injection mold. It is ideal for

bridge manufacturing and market testing.

-

Excellent Material

Properties: A wide range of polyurethane resins is

available, capable of mimicking the properties of various engineering

plastics, such as:

-

ABS-like: Good impact strength and toughness.

-

PP-like (Polypropylene-like): Good flexibility and fatigue resistance.

-

PC-like (Polycarbonate-like): High strength and heat resistance.

-

Transparent/Glass-like: For lens and light guide prototypes.

-

Rubber-like (TPE/TPU-like): For flexible, over-molded, or soft-touch parts.

-

High Fidelity and

Surface Quality: Vacuum Casting produces parts with

excellent surface finish, fine detail, and sharp reproduction of textures.

The surface quality is often superior to direct 3D printing.

-

Multi-Material and

Multi-Color Possibilities: Techniques like over-molding are

possible, where a rigid part is cast first, then placed back into the mold

to cast a second, soft-touch material over it.

4. Limitations

-

Limited Mold Life: The

silicone mold wears out with each cycle due to thermal stress and

mechanical tearing during de-molding. The maximum number of copies per

mold is typically 25-50.

-

Lower

High-Temperature Resistance: While there are high-temperature

PU resins, they generally cannot match the long-term thermal stability of

true engineering thermoplastics.

-

Material

Differences: Although PU resins mimic many

properties, they are chemically different from production plastics and may

behave differently under prolonged stress or specific environmental

conditions.

-

Size Constraints: The

size of parts is limited by the chamber size of the vacuum casting

machine.

5. Comparison with Other Technologies

|

Feature

|

Vacuum Casting

|

Injection Molding

|

3D Printing (SLA, SLS, FDM)

|

|

Best For

|

10 - 50+ parts, functional

prototypes, appearance models.

|

1,000 - 1,000,000+ parts, mass

production.

|

1 - 10 parts, concept

models, rapid iteration.

|

|

Tooling

|

Low-cost, fast silicone molds.

|

High-cost, slow steel/aluminum molds.

|

No tooling required.

|

|

Lead Time

|

Short for low volumes (days/weeks).

|

Very long for tooling, then very fast per

part.

|

Very short (hours/days).

|

|

Part Cost

|

Moderate per-part cost.

|

Very low per-part cost (after amortizing tooling).

|

High per-part cost.

|

|

Surface Finish

|

Excellent,

injection-molding quality.

|

Excellent.

|

Good to Fair (layer lines visible).

|

|

Material Choice

|

Wide range of mimicking PU resins.

|

Vast range of production thermoplastics.

|

Limited to specific printing polymers.

|

6. Common Applications

-

Functional

Prototyping: Testing the form, fit, and function of

a design.

-

Pre-Production /

Bridge Manufacturing: Creating parts for market testing,

clinical trials, or sales samples before committing to expensive injection

molds.

-

Appearance Models

and Sales Demos: High-fidelity models that look and

feel like the final product.

-

Small-Batch

Production: For niche products, custom parts, or

industries where volumes are low.

-

Over-molded Parts: Creating products with soft-touch grips or multi-material components.

In summary, Vacuum Casting is the

indispensable link between one-off prototyping and mass production,

enabling companies to de-risk the product development process and bring

high-quality products to market faster and more cost-effectively.