Background

Mastars applies photochemical etching on thin stainless sheet, then roll-forms, seam-welds, and electropolishes to deliver burr-free, zoned-porosity sleeves with predictable flow, fast design turns, and long service life.

The challenge

Juicer filters need tight control of hole size and open area to balance yield and pulp retention. Punching or laser drilling can leave burrs, heat tint, and shape drift that cause clogging, scraper wear, and frequent stops. Rapid pattern iteration across fruits is difficult when each change requires hard tooling.

Mastars solution

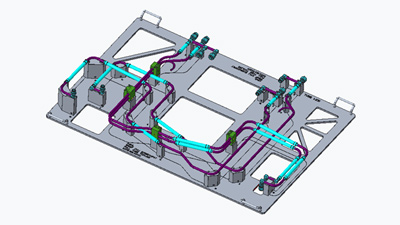

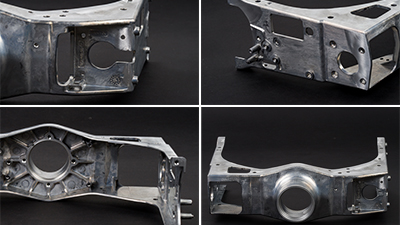

Mastars uses photochemical etching on flat 304/316L stainless backed by digital artwork zoning. Etched panels are precision roll-formed, laser or micro-resistance seam-welded, then electropolished and passivated. Inline optical inspection maps hole geometry and open area by zone; roundness, seam strength, and flow are validated before shipment. The same workflow scales from pilot runs to volume with full traceability.

System features

- Materials: 304/316L stainless; optional Ni alloys for acidic media

- Thickness: 0.05–0.30 mm typical

- Photochemical-etched perforations: ~80–600 μm holes with engineered pitch; zoned open area

- Open-area tolerance: typically ±1–2% of target across the sheet

- Forming and seam: controlled arbors for roundness; monitored overlap and continuity

- Finish: electropolish and passivation; smooth surfaces compatible with CIP routines

- Quality package: AOI 100%, flow/pressure-drop checks, seam burst/torque tests, traceable lots

-

Benefits

- 1)Burr-free micro-perforation reduces clogging, lowers blade/scraper wear, and extends run time

- 2)Predictable flow and pulp profile via tight hole-size control and zoned porosity maps

- 3)Fast design iteration as digital masks update in days

- 4)Stable geometry with controlled roundness and seam integrity for uniform gaps to rotating elements

- 5)Cleanability improved by electropolished surfaces that resist residue adhesion

-

Use cases

Juicer and beverage filters: centrifugal and masticating juicers, cold-press pre-screens, clarifying stages, seed-removal drums.

Beyond juicers — applications of photochemical etching:

- Automotive: micro-perforated muffler cores and HVAC silencers, fuel and ATF pre-screens, battery vent shields.

- Electronics: speaker and microphone meshes, airflow grills, EMI vent screens.

- Laboratory & process: precision sieves, sample screens, gas/liquid distributors and flow straighteners.

- Aerospace & energy: lightweight burner/injector screens, protective filters for fluid circuits.

If you have better ideas, please contact Mastars today. Where great ideas are built.