Mastars' industrial rapid prototyping service, with products and services that exceed customer expectations, is well-known in Europe and the United States, and has a high customer reputation. The industry covers a wide range of fields, including automobiles, motorcycles, health care, outdoor sports, home appliances, household goods, 3C Electronics, agriculture and stage lighting, etc.

The road of development of Mastars is changing due to the necessary of high technology.

We need to produce more exact mechanical equipments and complex and presicion semiconductor devices.we are producing kinds of semiconductor devices,the raw material are stainless steel,brass, titanium, tungsten,Zinc,alloy zinc,Aluminium alloy etc. and sorts of engineer plastic material,process according to requirement of customer(strict tolerance(like H6,H7,N7,ISO2768 etc.),the most precision tolerance we can reach +/-0.01mm,we also have exact requirements about the X,Y,Z axis,parallel,vertical tolerance.

Regarding the cleaness of device,our customer is asking grade4-6,we have our own dust free workshop,all components are assembled in dust free workshop after ultrasonic or dry ice cleaning in order to achieve the cleaness asked by our customer. Some special plastic parts are assembled after cooled by liquid nitrogen.

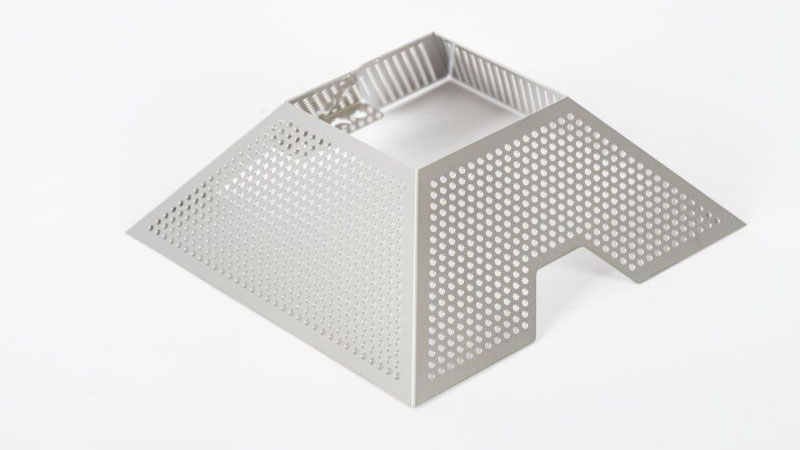

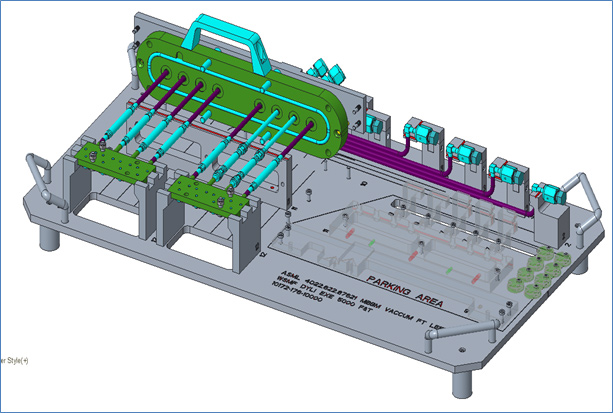

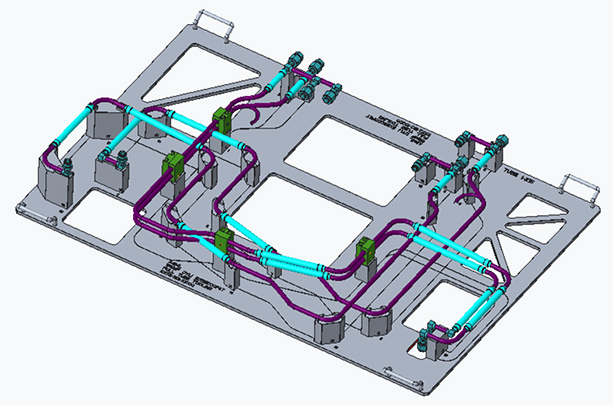

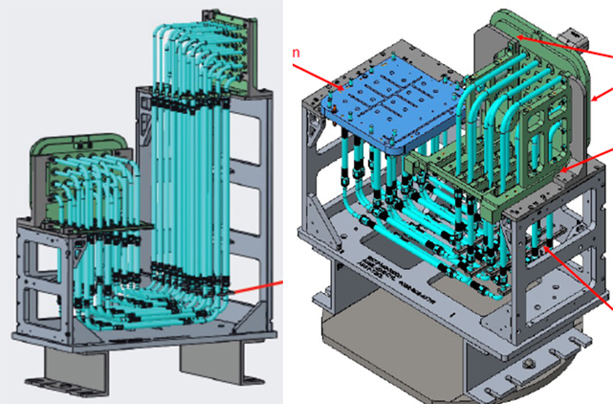

The below devices are produced by our prototype department,they are exceeded the expection of our customer whatever surface treatment,exact dimension,perfect fitting of assembly,we have completed 15 sets difference device for this series production,for the 140 and 141 devices,we processed over 30 sets and all are finished by our prototype department.

This device are including main plate,blocks,pipe and assembly standard parts,the main raw material are Aluminium alloy ,stainless steel,the flow of process is from CNC,sheet matel,anodizing,engraving,cleaning,CMM measuring,welding assembly,FAI for assembly device,test,cleaning again,vacuum package, to safe packing and ship out by air.

“Craftsman spirit” is our original intention and never forget.

Every component,every working process,every device,they all are our attitude about production,there is only one thing in our eyes and heart,that is more and more exact of quality and meticulous of producing,no other more except it.