This case study provides a detailed analysis of how a leading automotive manufacturer (OEM) utilized additive manufacturing technology for the rapid prototyping of an intake manifold in a new high-performance turbocharged engine project. Faced with a compact engine bay layout, demanding performance targets, and a tight development schedule, traditional prototyping methods were insufficient. By adopting polymer 3D printing technologies like Selective Laser Sintering (SLS) and MultiJet Fusion (MJF), the team achieved rapid iteration of the intake manifold's geometry, functional validation, and performance optimization. This approach slashed the prototyping cycle from several weeks to just a few days and resulted in a final product that outperformed traditional designs and was lighter in weight. This case demonstrates how rapid prototyping technology solves complex engineering challenges and sits at the heart of modern agile development processes.

Project Goal: Develop a 2.0-liter turbocharged engine for a high-performance sports sedan, requiring a 15% increase in power and torque output over the previous generation. Additionally, the maximum torque plateau needed to begin at a very low 1500 rpm to improve low-speed response.

Critical Component: The intake manifold. This component is responsible for distributing clean, cooled air from the turbocharger and intercooler evenly to each cylinder. Its internal geometry, airflow channel smoothness, and the volume and shape of the plenum directly determine the engine's breathing efficiency, cylinder-to-cylinder uniformity, and ultimately, its power and emission levels.

Challenges:

Extremely Limited Space: The new engine featured a more compact block structure, leaving an unusually small and confined space for the intake manifold, making traditional "rectangular" designs impossible to install.

Stringent Performance Targets: The requirement for a wide torque plateau meant the airflow within the intake manifold had to remain efficient across all engine speeds, from low to high, posing significant challenges to the internal runner design.

Tight Development Timeline: With a strict market window, the entire engine development cycle was compressed, allowing only half the time of a traditional project for the intake manifold's design and validation.

Bottlenecks of the Traditional Method:

Before the widespread adoption of rapid prototyping, the typical development process for such a complex component was:

Designers created a preliminary design using CAD software.

Computational Fluid Dynamics (CFD) software was used for simulation analysis.

An aluminum mold (hard tooling) or an epoxy resin mold (soft tooling) was manufactured.

1-5 physical prototypes were produced using injection molding with engineering plastics like nylon.

This process typically took 4-8 weeks and cost tens to hundreds of thousands of dollars. If the CFD analysis or subsequent bench testing results were unsatisfactory, the entire process had to be repeated, causing significant delays and cost overruns. The high risk discouraged designers from pursuing bold, innovative design attempts.

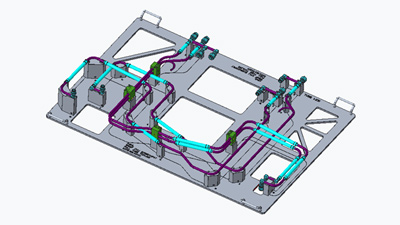

The project team decided to abandon the traditional tooling route and fully adopt additive manufacturing for the rapid prototyping of the intake manifold. The integrated workflow is illustrated below:

[Chart Description: Intake Manifold Rapid Prototyping Iteration Flowchart]

Cycle Start:

Step 1: Innovative Design & CAD Modeling – Engineers engaged in free creative design, leveraging insights from CFD simulations on fluid dynamics. They designed complex internal airflow channels, optimized swirl generation structures, and an exterior shape that perfectly conformed to the remaining space in the engine bay. Designs were liberated from the constraints of traditional manufacturing processes (like draft angles, parting lines).

Step 2: High-Fidelity CFD Simulation – The CAD model was imported into advanced CFD software for detailed airflow analysis, predicting key metrics like flow coefficients, pressure loss, and cylinder uniformity.

Step 3: Additive Manufacturing (3D Printing) – The optimized CAD model was sent directly to an industrial-grade 3D printer. Nylon-based materials (e.g., PA12) were used with SLS or MJF technology. A complete intake manifold prototype could be printed in 24-48 hours.

Step 4: Post-Processing & Inspection – After printing, the part was retrieved, excess powder was removed, and necessary surface treatments (e.g., bead blasting, sealing) were applied to improve smoothness and meet functional test requirements. The finished part was inspected using a 3D scanner to ensure it matched the CAD model perfectly.

Step 5: Bench Functional Testing – The physical prototype was installed on an engine test bench for real-time testing. Real data on flow, pressure, and temperature were collected, and the engine's overall performance (power, torque, emissions) was evaluated.

Step 6: Data Comparison & Iteration – Real data from bench testing was compared with the CFD predictions from Step 2. Differences were analyzed, and the CFD model was calibrated to make it more predictive for future iterations. Based on the test results, directions for design improvement were identified.

Cycle End / Return to Step 1: Based on test feedback, the CAD model was modified, and a new iteration cycle began.

Using this process, the team completed 12 completely different intake manifold design iterations and manufactured and tested over 30 physical prototypes within three months. The specific outcomes were as follows:

1. Exponential Reduction in Development Time and Cost:

Time: The single iteration cycle was reduced from "several weeks" to "a few days." Printing itself took only 1-2 days, and with post-processing, shipping, and testing, a complete design-build-test cycle could be completed within a week.

Cost: The cost per 3D-printed prototype was only a few hundred to a thousand dollars (depending on material and volume), negligible compared to the tens of thousands for tooling. This made extensive, rapid "trial and error" economically feasible.

2. Revolutionary Increase in Design Freedom:

The team was able to realize previously un-manufacturable designs:

Integrated Plenum Chamber: Designed a highly complex yet highly efficient plenum chamber, printed in one piece with the main manifold body, eliminating additional assembly and significantly improving low-rpm torque response.

Airflow-Optimized Structures: Printed internal guide vanes within the pipes to direct airflow with lower resistance and greater uniformity to each cylinder. Such structures are impossible to create with traditional injection molding.

Topology-Optimized Structure: While ensuring structural strength in key areas, the manifold's outer shell was topology-optimized, printing a lattice-like support structure that reduced weight and used material more efficiently.

[Image Description: Side-by-side comparison. Left is a traditional black injection-molded intake manifold with a relatively simple structure. Right is a 3D-printed grey prototype, featuring complex internal lattice and organic piping, visually demonstrating the design difference.]

3. Substantive Breakthrough in Function and Performance:

Performance Validation: The final selected design, during engine bench testing, achieved a 22% reduction in pressure loss and a 15% improvement in cylinder uniformity. This directly contributed to the engine achieving 90% of its maximum torque at 1500 rpm, perfectly meeting the project goal.

Weight Reduction: Through structural optimization, the final 3D-printed prototype was 18% lighter than an equivalent traditional design.

Higher Simulation Accuracy: The multiple cycles of "CFD prediction -> physical test validation" provided valuable data that greatly calibrated and improved the accuracy of the CFD models, laying a stronger foundation for future virtual development.

During the fifth design iteration, CFD simulation indicated airflow separation occurring at a specific bend in the intake manifold, causing turbulence and pressure loss. The traditional method would have required new tooling, consuming significant time and money.

The Additive Manufacturing Solution:

Problem Identification: Bench test data confirmed the CFD prediction, showing a measurable pressure drop in that region.

Rapid Modification: Engineers made fine adjustments to the bend's curvature in the CAD model and added two small guide fins.

Rapid Validation: The modified model started printing that evening, and a new physical prototype was ready the next afternoon. After brief surface smoothing, it was installed on the test bench on the third day.

Result: Test data showed the turbulence was eliminated, and the pressure loss was reduced as expected. The entire process, from identifying the problem to verifying the solution, took only 4 days.

The success of the intake manifold development project fully demonstrates the core value of additive manufacturing rapid prototyping in solving modern automotive engineering challenges. It is not merely a tool for "making models quickly" but a paradigm shift that enables engineering innovation:

From "Design for Manufacturing" to "Manufacturing for Design": Engineers can prioritize functional performance, no longer constrained by manufacturing processes.

Accelerated Learning Cycles: The extremely short iteration cycles allow teams to explore more design possibilities and learn quickly from physical tests, leading to better engineering decisions.

Reduced Innovation Risk: Low-cost prototyping allows for bold experimentation and "failure," from which true breakthroughs often come.

Looking forward, with advancements in metal 3D printing and higher-performance materials, the application of rapid prototyping will expand from non-critical structural components like intake manifolds to more critical, durable parts such as turbocharger wheels, engine mounts, and even customized cooling channels. Rapid prototyping has become an indispensable part of the automotive R&D system and a key driver for continuous product innovation and maintaining competitiveness.