Mastars uses the industry-leading testing equipment and technology to control every step of the production process from rapid prototyping services to mass production delivery, so that each production step can be qualified in time and the whole production process can be carried out smoothly. In general, this not only ensures the high qualification rate of products, but also shortens the production cycle and greatly reduces the time cost.

Our testing center has advanced comprehensive testing equipment, such as German GOM ATOS III TRIPLE Scan Blue ray 3D scanner, Swedish Hexagon CMM, 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan Mitutoyo Roughness Meter, etc. All this ensure that your products meet the design and functional requirements.

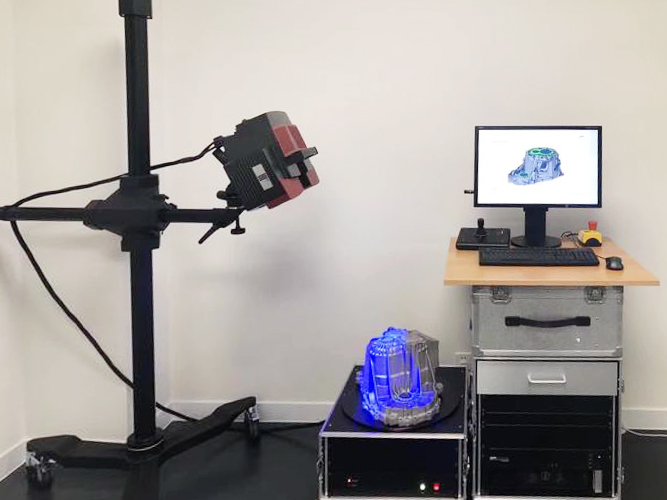

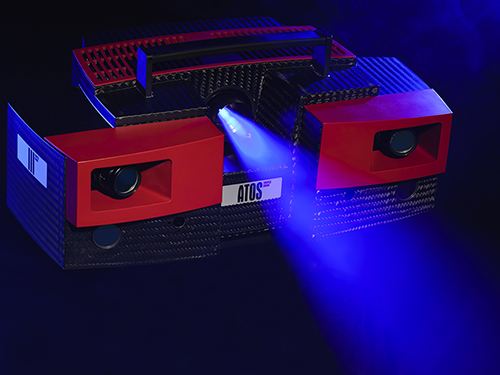

German GOM ATOS III TRIPLE Scan Blue ray 3D scanner

The German GOM ATOS III TRIPLE Scan high-end optical non-contact 3D scanner is mainly composed of grating projection equipment and two industrial-grade CCD Cameras. Its principle is just like two pairs of human eyes. The grating is projected on the object to be measured, and the thickness and displacement are changed. Combined with CCD Camera, the digital image captured by computer is processed to obtain the 3D scanning appearance of the object to be measured.

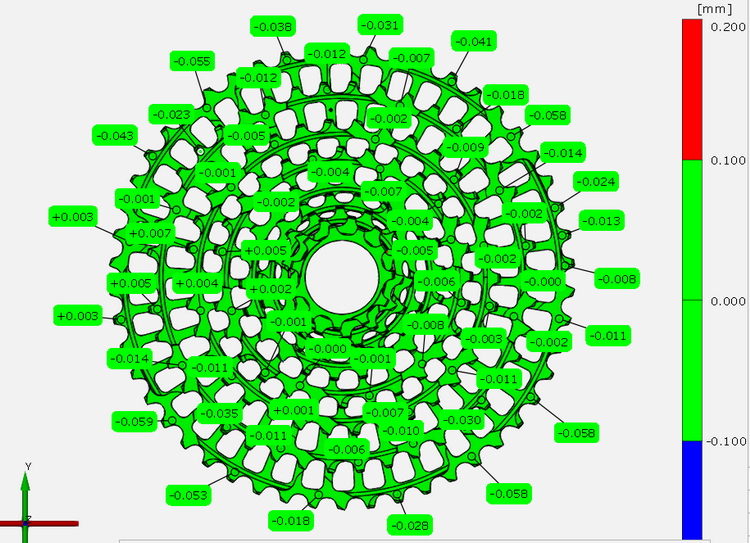

A single measurement data can extract 8 million points from the image. After the measurement of the entire object is completed, all the point groups are superimposed to form the 3D shape of the real object, and then the data in STL format is generated by calculation. The computer automatically locates the scanned data, making ATOS a mobile scanning system, so no matter how complex the measured object is, it can be scanned quickly.

The freely changeable scanning range of ATOS makes it have a wide range of scanning flexibility, no matter whether the object being measured is like the whole car or like a grain of rice, there is no size limit of the measured object during the scanning process.

It is used for 3D number copy, reverse engineering, deformation analysis, etc. The highest precision can reach 0.007mm.

The scanning data of ATOS not only has high precision and fine details, so its application range is very wide.

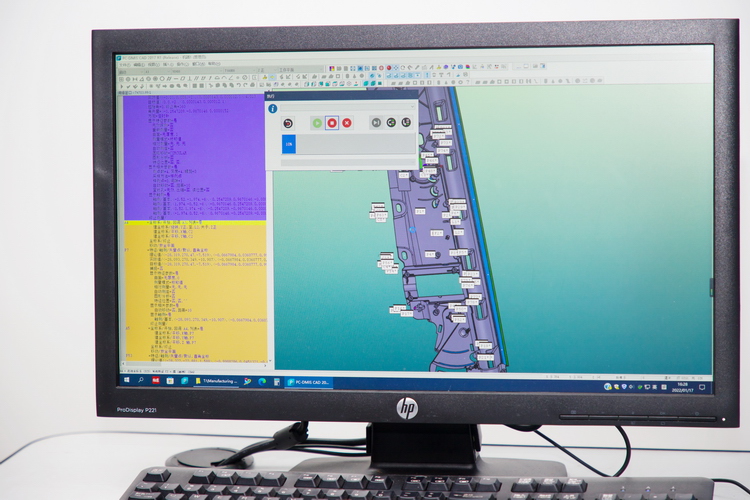

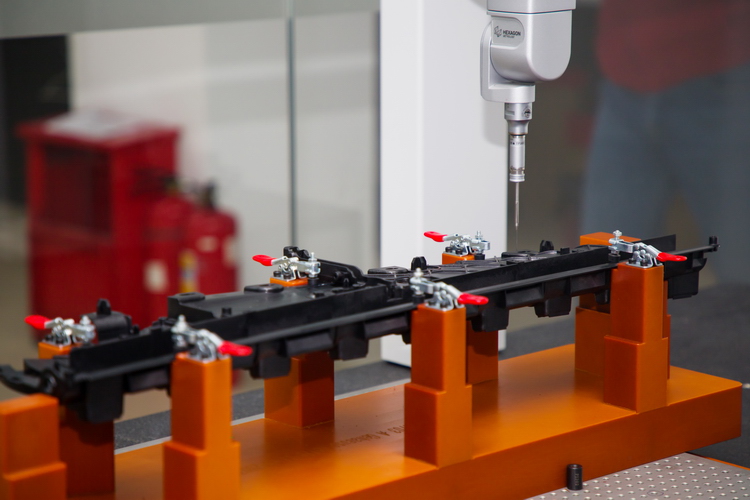

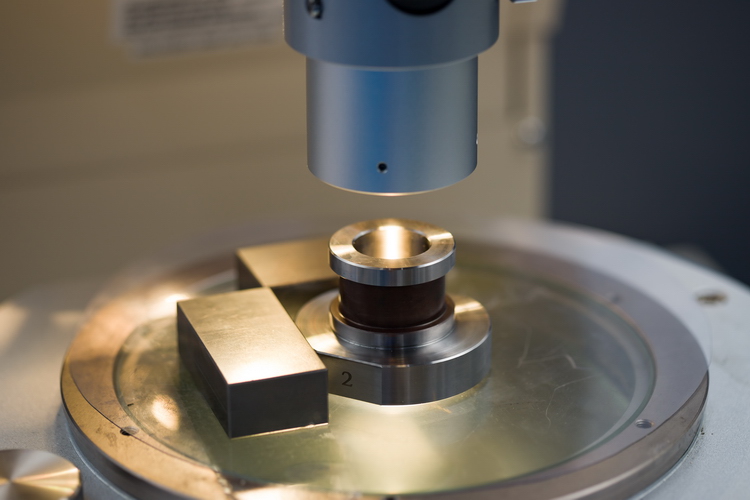

Hexagon Classic SR 7107 series CMM

Hexagon is the world's largest manufacturer of CMM instruments. Hexagon Classic SR 7107 series CMM, is the latest generation of high performance mobile bridge measuring machines with a high stability, precision and efficiency measurement system that can be programmed to measure position, profile, etc. It can meet the general detection needs quickly and efficiently. Besides, it is equipped with PC-DMIS software, which is recognized as the most powerful general purpose measurement software in the industry.

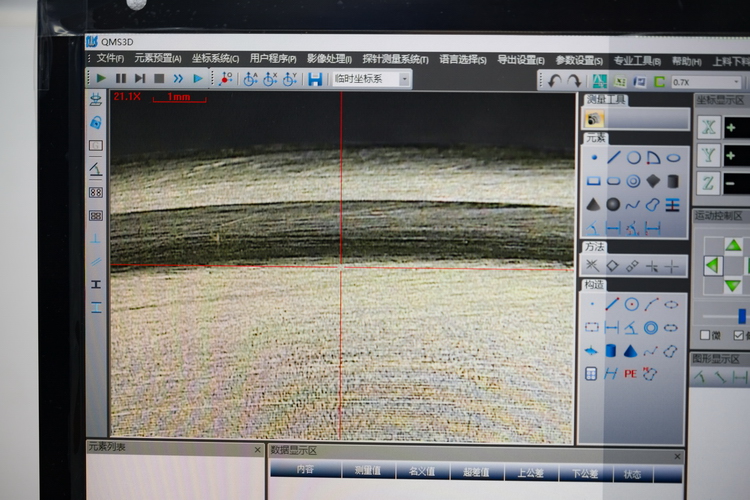

Rational VMS-4030H

Rational VMS-4030H 2.5-dimensional automatic image measuring instrument is mainly suitable for all application fields for the purpose of two-coordinate measurement, and it is widely used in machinery, electronics, plastics, molds, hardware manufacturing and other industries. Because it integrates light, machine, Electric, computer graphics technology, through high-precision lens imaging, micro-detection of precision parts can be carried out. For example, the contour, surface shape, size, angle and position of various complex workpieces can be effectively measured, and the measurement can be converted into statistics and charts. Measurement precision: 2.5+L/100 μm.

Hitachi X-MET8000 handheld X-ray fluorescence spectrometer

Hitachi X-MET8000 handheld X-ray fluorescence spectrometer is used for rapid grade identification of alloys and accurate chemical structure analysis of a variety of materials (solid and powder metals, polymers, light elements (magnesium, aluminum, silicon, phosphorus, sulfur, chlorine), wood, solutions, soil, ores, minerals, etc.). It can provide you with reliable results.

Swiss TESA micro-hite600

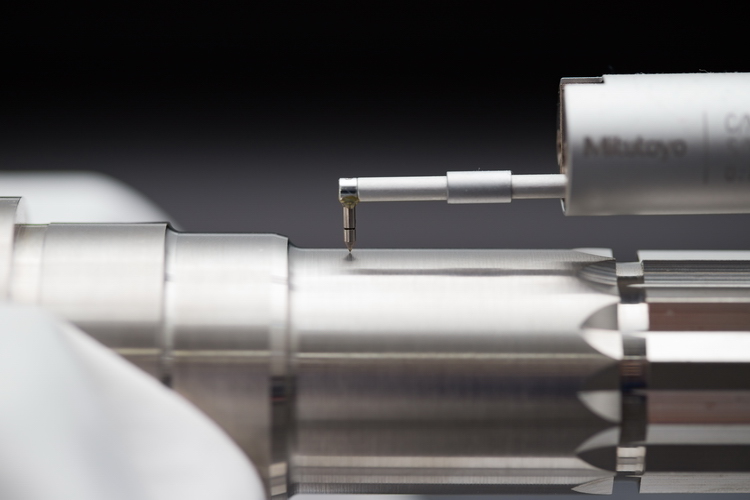

Mitutoyo SJ-410 roughness meter

Mitutoyo SJ-410 roughness meter, the brand comes from Mitutoyo precision instrument equipment manufacturer in Japan. It is also widely used in hardware manufacturing, mold tooling and other industries; it is mainly used to measure the surface roughness (smoothness) of hardware products, plastic products and so on . Measuring range: 800μm Resolution: 0.0001um.

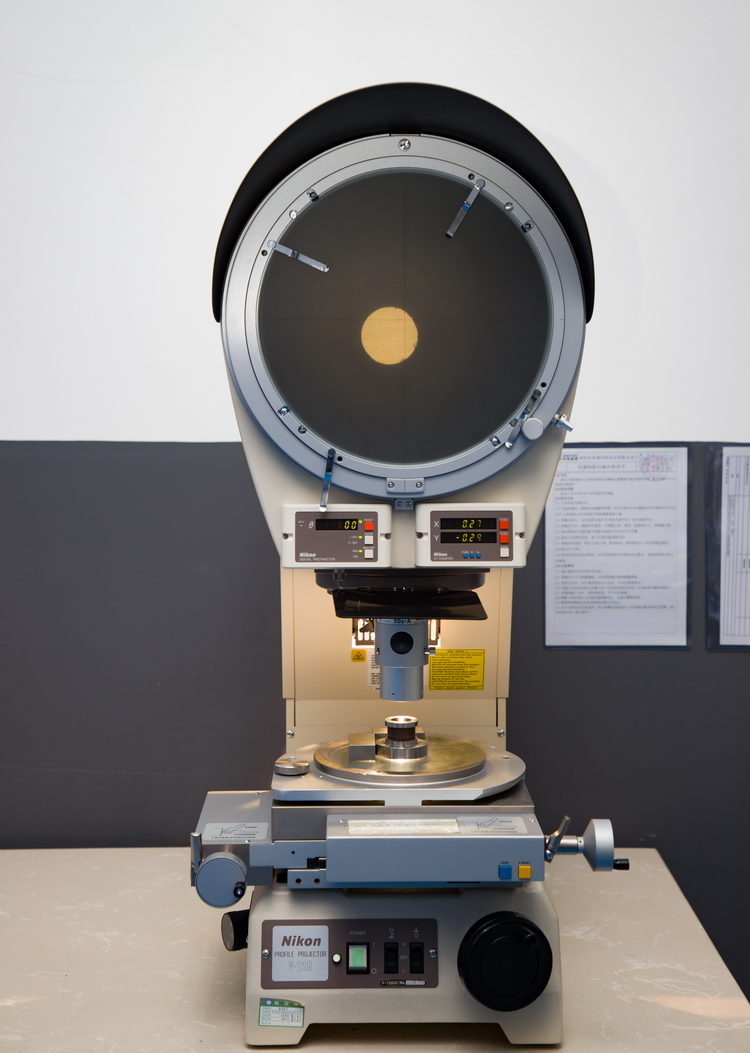

Nikon V-12B profile projector

Nikon V-12B profile projector, used for enlarged projection inspection, measurement, comparison, photography, list recording of size, length, shape, and profile, with an accuracy of 0.0002mm.

Mastars:

We employ proven prototype technologies(CNC machining, Vacuum casting, 3D printing etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Our purpose is to make great products for our customers that create value and improve people's lives. We help a diverse customers base design, build and deliver the products that make the world a better place.

Our vision is to be the most reliable and valuable manufacturer supplier in the world.