-

-

Mastars: What is Vacuum Forming?A sheet of plastic is heated to a melting point, stretched over a single-surface mould, and pressed against the mould by...

-

-

Precautions for aluminum parts processing|rapid prototyping services|mastarsThere are many materials of products processed by CNC machine tools, among which aluminum parts are one of the most proc...

-

-

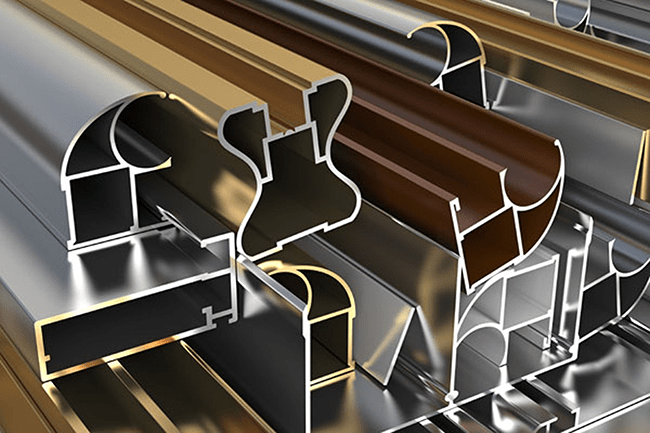

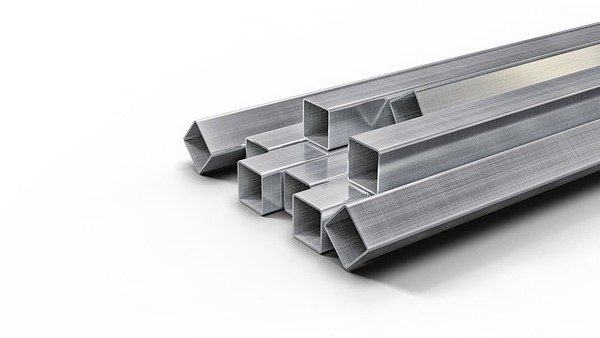

Mastars: All You Ever Wished to Know About Aluminum ExtrusionAluminum extrusion is solid and semi-hollow designs made from aluminum. Since aluminum is a great conductor of heat, it ...

-

-

Mastars: Aluminum vs Steel Tooling Injection MoldingHow to build a proper tool is critical for a new project. We always looking for the right material to produce the right ...

-

-

Understanding the New Product Introduction (NPI) Process|Rapid prototypingCreating a new product means managing a ton of moving parts simultaneously. You have to make sure your team is communica...

-

-

Mastars: What is rapid prototyping technology manufacturing and its characteristWith the competition in the manufacturing industry is fierce, and the speed of product development has increasingly beco...

-

-

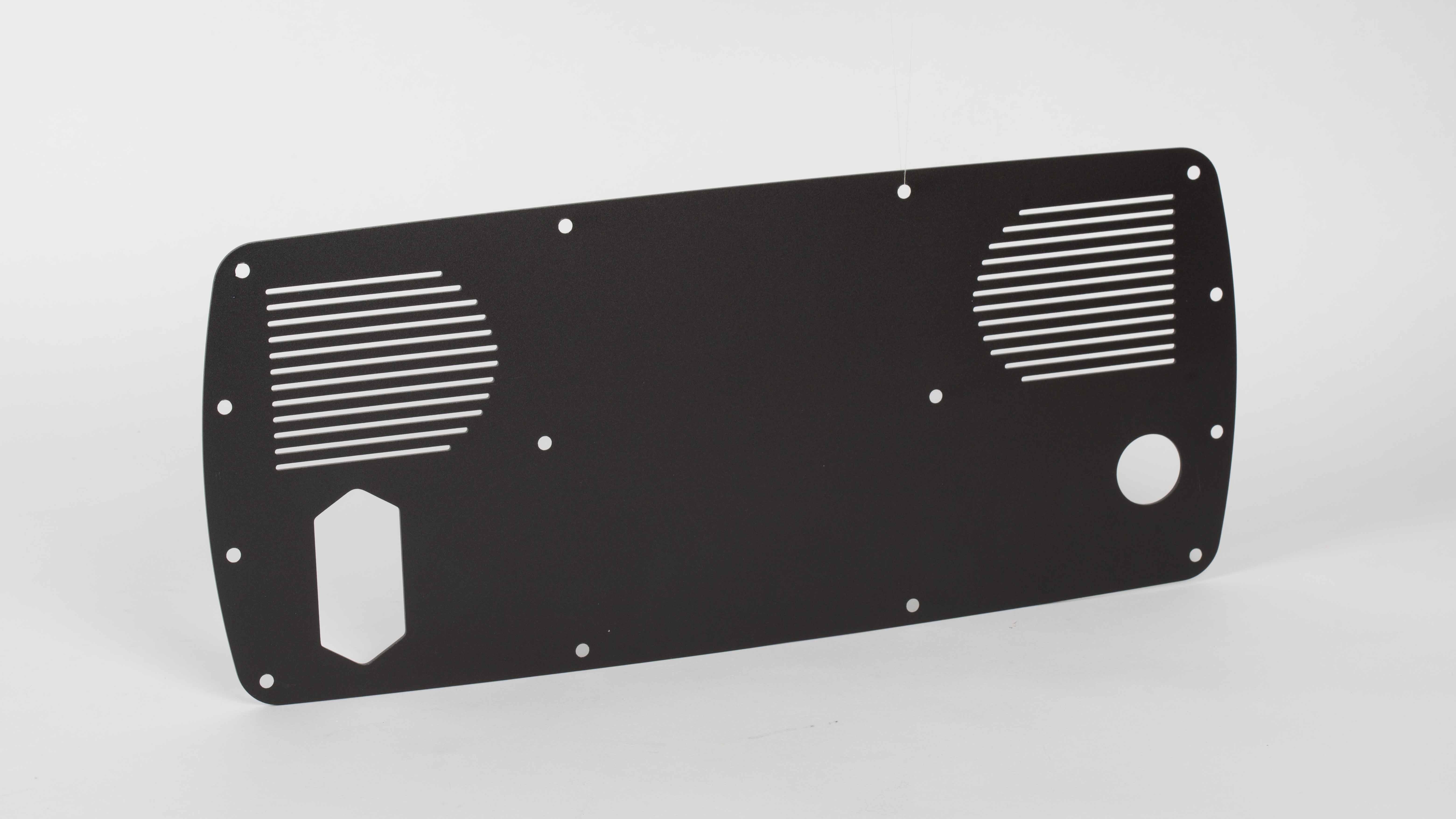

How to prevent corrosion after sheet metal processing?|metal prototype makerFor sheet metal products, most materials except stainless steel require anti-corrosion, anti-rust and anti-oxidation. Ma...

-

-

Mastars introduces you to Multi Jet Fusion technology|rapid prototyping servicesMJF technology claims to have much faster printing speed and much higher material utilization than other additive manufa...

-

-

Material selection precautions of metal stamping die|rapid prototyping servicesMastars provides one-stop industrial manufacturing customization services from prototype to mass production. Rapid sheet...

Contact us

- Building 6 , Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City,Guangdong, China (518104)

- marketing@mastars.com

How to make full use of CNC punch die|Prototype manufacturer Mastars

Mastars specialize in CNC machining /CNC Rapid prototyping/3D printing/Vacuum die casting/metal prototype maker . Familiar with casting, extruding,forging, CNC machining, moulding, custom metal stamping,and also finish treatments.

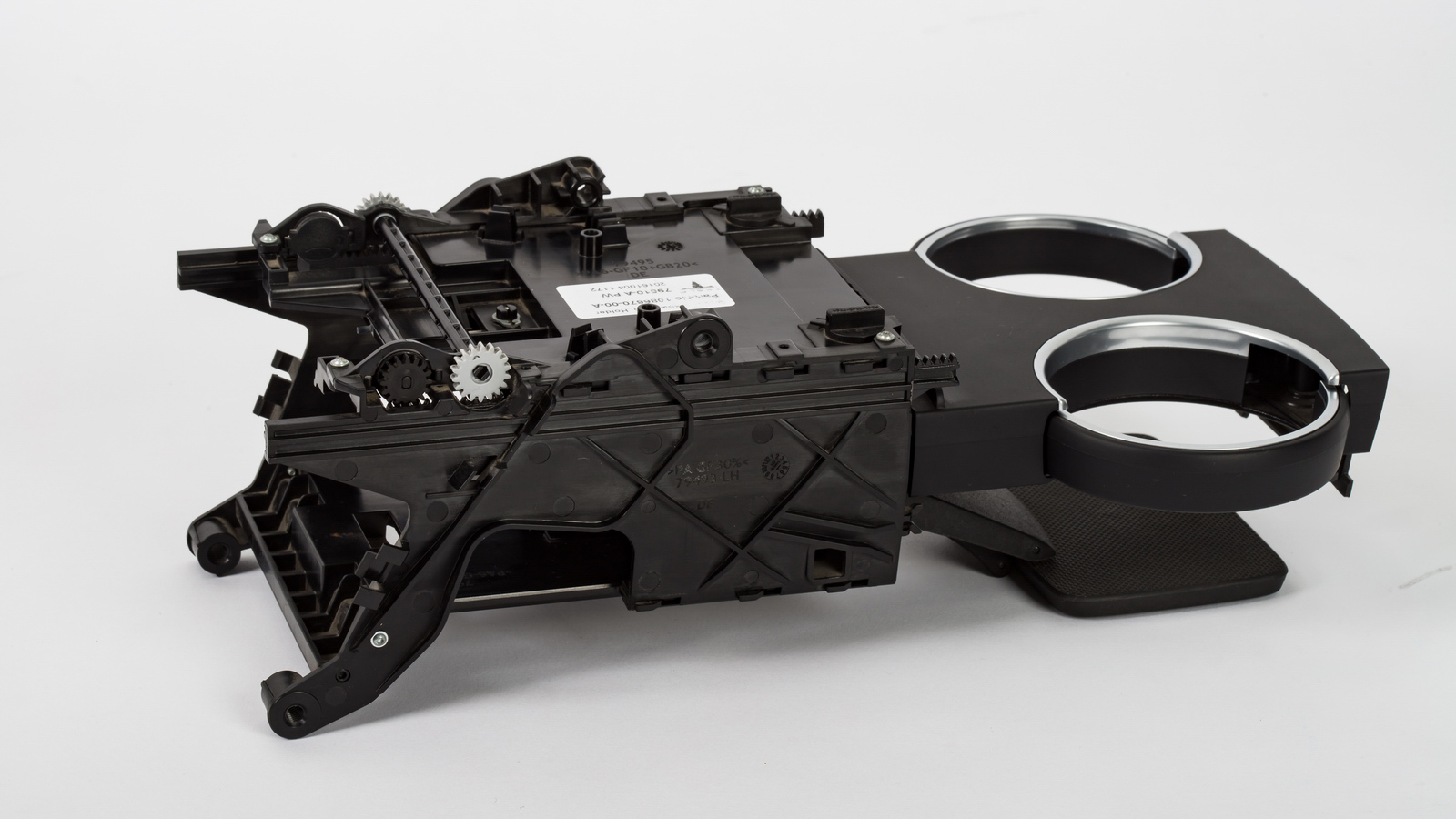

In the sheet metal industry, how to make full use of CNC punch molds correctly, so as to improve the production efficiency of machine tools and reduce the average manufacturing cost of sheet metal parts has always been the goal of various enterprises. In today's increasingly fierce market competition, it has become one of the difficult problems perplexing production managers and supervisors. How to improve the effective running time of machine tools is the key to solve these problems. Especially when we understand the processing capacity of our own machine tools and the characteristics of products, and optimize the use and layout of NC punch molds on this basis, we will have a full understanding of the importance of improving the effective running time of machine tools. If we ignore these elements, we will spend a lot of time on time-consuming die installation and debugging, secondary processing and slow stamping, which greatly wastes the powerful processing capacity originally given to the machine tool.

Methods of optimizing programming and design

1. Adopt reasonable product design

2. Combined with creative programming

1. Use standard turret layout

2. Control the production in the mold room

3. Minimize the difference of mold types

4. Maintain the mold frequently and regularly

5. Install the quick change mold

Carry out the correct lower die clearance and quickly adjust the punch station

No matter what kind of parts you need, as long as you have drawings, we can help you.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

【Editor】:Mastarsall rights reserved:https://www.mastars.comPlease indicate the source