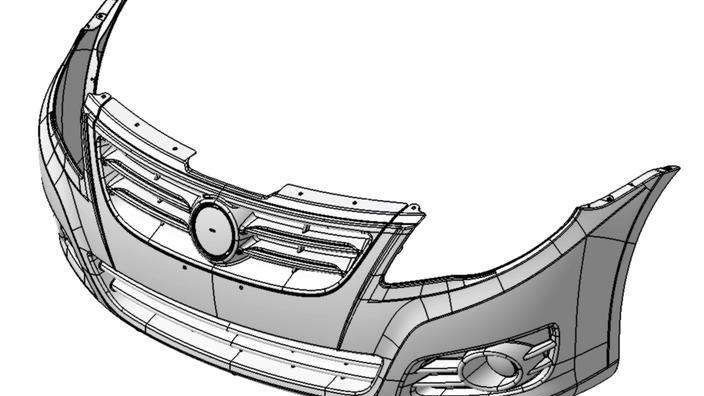

Mastars is dedicated to the extrusion, injection molding, and machining of various plastic products. We specialize in PEEK, PI, PPS, PEI, and provide special engineering plastic finished parts and semi-finished profiles for different industries.|rapid cnc machining|Bumper Mould

Many people know that the mainstream material of automobile bumper is plastic. In our impression, isn't steel stronger than plastic? Why do manufacturers prefer to use plastic to make bumpers? In fact, there are several reasons:

Compared with steel, plastic materials and processing costs are lower, so the use of plastic bumpers can greatly save manufacturing costs. After the manufacturing costs are controlled, the price of final products to consumers will become cheaper. Of course, in addition to plastic bumpers, some top sports cars will be made of carbon fiber, and the price will naturally be higher.

If the bumper is made of rigid materials such as iron or steel, once it hits a pedestrian, the injury to the pedestrian will be fatal. Due to the material, the plastic bumper is more elastic than the rigid metal, and can also absorb the impact energy, so the plastic insurance can also play a role in protecting pedestrians.

In the process of driving and using the car, the front and rear bumpers are more vulnerable to scratches and bumps, and contact with water marks and other substances is more frequent. The primer is easy to be exposed after the metal parts are scratched. If the paint is not repaired for a long time, it is easy to rust and corrosion due to moisture as time goes by. The plastic material has the advantages of corrosion resistance and rust prevention, so it has naturally become a better choice.

Of course, the plastic used to make bumpers is not our common plastic. At present, domestic automobile front and rear bumpers generally use toughened polypropylene material as raw material for injection molding - polypropylene plastic (commonly known as PP material), which has the advantages of high melting point, heat resistance and corrosion resistance. Its products have relatively good strength, rigidity and transparency, high rigidity, impact resistance, scratch resistance and paintability, and will not break under the impact of 8 km/h, And has the elasticity of recovery.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China